How Are Championship Rings Made? Unveiling the Craftsmanship Behind Custom Jewelry

The championship ring, a timeless symbol of glory and achievement, is the ultimate treasure sought after by every championship team and athlete. But have you ever wondered how this seemingly simple yet meaningful ring comes to life? What do its design, craftsmanship, and the stories behind it truly represent? Today, we’ll take you on a journey to uncover the step-by-step craftsmanship of championship rings, showing you how they are transformed from concept to reality!

How to Begin Customizing a Championship Ring?

The process of crafting a championship ring consists of several key steps:

Design – Material Selection – Craftsmanship – Production – Quality Control, with every step demanding precision and meticulous attention to detail.

✧ Design Stage: From Concept to Concrete Proposal ✧

Before initiating the design process, HUNGKUANG will confirm the delivery or award date with the client. Since the process of creating a championship ring—from design to production—requires considerable time, we prioritize assessing whether the schedule is sufficient and determining the feasible designs within the given timeline.

Typically, the duration of the design phase depends on the number of discussions and revisions. With efficient communication, the design can be finalized within 7 days, while production generally requires at least 35 to 40 days.

Next, HUNGKUANG's professional team conducts in-depth discussions with the client to understand the story and values they aim to express through the ring.

To gather more specific details, we ask essential questions such as:

• What symbols should be included on the ring (e.g., team logo, championship name)?

• Is a personalized design required (e.g., player names, jersey numbers)?

• Do you prefer a more luxurious or minimalist style?

• Do you have a favorite championship ring design or shape?

If you have reference images of preferred designs, it will help us better understand your style preferences!

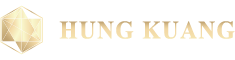

✧ 3D Modeling and Design ✧

Once the concept is finalized, we utilize advanced 3D modeling software to transform the design into a precise three-dimensional model. Throughout this process, we maintain close communication with clients, offering real-time feedback and implementing necessary adjustments. Finally, we provide detailed three-view drawings for clients to confirm all dimensions and intricate details.

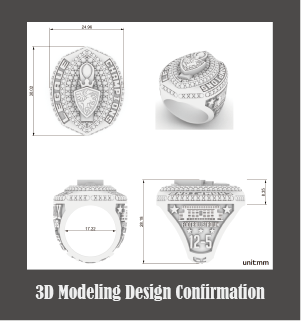

✧ Sample Production ✧

Depending on the client's specific needs, HUNGKUANG provides the following optional methods for design confirmation:

✔ To verify the actual size and details of the championship ring, we offer 3D-printed wax samples, which can be produced and shipped within a single day.

✔ If you wish to evaluate the actual texture and quality of the championship ring, HUNGKUANG will recommend creating a physical sample. This step is optional and typically takes 30 to 35 days, depending on the material specifications.

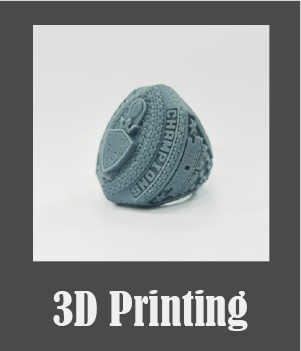

✧ Final Rendering Confirmation Before Production ✧

After verifying the product design and dimensions, we provide detailed 3D renderings for final approval. These renderings meticulously showcase every aspect of the championship ring, including gemstone size, color, shape, paint positions, specific paint codes, as well as plating materials and coverage areas.

Once all details are approved, we proceed with mass production. Before shipment, each championship ring undergoes HUNGKUANG's rigorous two-stage quality control process to ensure flawless craftsmanship before being carefully packaged and delivered.

Material Selection: The Key to Quality and Appearance

Championship rings are typically crafted from precious metals and gemstones, and the choice of materials directly impacts the ring's texture and value.

Metals: Commonly used materials include gold, white gold, and platinum, which are not only durable but also emphasize a sense of luxury. Alternatively, brass or sterling silver are also popular options for many clients.

Gemstones: The gemstones on the ring are often diamonds or synthetic stones. If special effects are desired, HUNGKUANG can also incorporate colored gemstones to reflect the team's representative colors based on specific requirements.

You May Also Be Interested In...

Championship Ring Production Process

Pre-Casting Preparation: The creation of a championship ring involves a meticulous and multi-step process, supported by standardized procedures and expert craftsmanship to guarantee exceptional quality. Initially, designers utilize advanced 3D modeling software to construct a detailed digital model. This is followed by prototype development and the creation of a silicone mold to facilitate mass production. During the wax injection stage, molten wax is carefully poured into the mold to produce precise wax models, which are then assembled into a “wax tree” to optimize production efficiency.

Gemstone Settin: According to the design specifications, diamonds or selected gemstones are meticulously set into the ring with precision.

Casting and Production: In the next phase, molten metal is carefully poured into the plaster mold. Once cooled, the mold is removed to unveil the metal prototype, which undergoes an initial stage of polishing and refining to enhance its appearance. Following this, gemstones are set, or laser engraving is performed in accordance with the design requirements. The final step involves additional polishing and a thorough, multi-stage quality inspection to ensure each ring meets the highest standards of craftsmanship.

Partial Enamel Coating: HUNGKUANG employs a high-precision enamel coating process that achieves uniform coverage, even on the most intricate details, delivering a smooth and refined texture. Whether applied to subtle textures or complex three-dimensional designs, every stroke of enamel is meticulously executed to guarantee a flawless and polished finish.

Jewelry Electroplating: The jewelry undergoes meticulous polishing and thorough cleaning before being immersed in a plating solution containing metal ions. By applying an electric current, a uniform and durable metallic layer is deposited onto the surface, enhancing both the appearance and durability of the piece.

This comprehensive process not only ensures production efficiency but also guarantees uniformity in detail and exceptional quality, solidifying each product as a lasting symbol of honor and craftsmanship.

Craftsmanship: From Details to Perfect Presentation

Every step in the production of a championship ring requires precise technical expertise.

Micro-Pavé Stone Setting

This is a technique for setting tiny gemstones onto the ring. HUNGKUANG's production team precisely places each gemstone in its designated position, ensuring both brilliance and durability of the ring.

Text Embossing Design

Embossing is used to engrave text and patterns onto the ring, such as team logos or championship names. Using advanced engraving machinery, HUNGKUANG achieves exceptionally detailed results even on small surfaces.

Laser Text Engraving

This technology is primarily applied in large-scale production for engraving personalized details, such as player names and jersey numbers. It is both efficient and highly accurate.

Jewelry Enamel Coating

The core of HUNGKUANG's enamel coating process lies in the precise control of coating thickness and positioning, preventing color overflow or grainy textures from affecting the final appearance of the product.

This process not only ensures production efficiency but also guarantees consistency in the details and quality of each product, making it a true symbol of honor.

Differences Between Individual Customization and Mass Production

Single Customization

Exclusive Molds: Each ring requires the creation of a unique mold to ensure the design meets specific individual needs.

High Degree of Personalization: The design can be tailored to accommodate the unique preferences or requirements of each team member.

Higher Cost: The requirement for multiple molds and the time-intensive production process result in higher costs.

Mass Production

Shared Molds: A single mold is used to efficiently produce multiple rings.

Personalized Details Added Later: Custom details, such as player names or jersey numbers, are uniformly applied through laser engraving.

Lower Cost: Its high efficiency makes this process ideal for large-scale orders.

Quality Inspection: Delivering Perfection in Every Ring

Every championship ring from HUNGKUANG undergoes meticulous quality inspection to ensure flawless delivery.

• The surface is meticulously checked to ensure it is smooth and flawless.

• Each gemstone is tested to confirm it is securely set.

• Laser-engraved text is inspected to guarantee clarity and precision.

• Accessories are verified to match the design specifications.

Why Choose HUNGKUANG? Our Expertise and Commitment

With over 20 years of experience in the jewelry industry, HUNGKUANG boasts extensive production expertise as a leading jewelry manufacturer. We understand that customers may not always be familiar with the design and manufacturing process. Therefore, from the initial concept to the final product, we provide professional guidance at every stage to ensure that the final product meets your expectations and brings your vision to life.

The Assurances HUNGKUANG Provides:

Tailored Problem-Solving Services:

At HUNGKUANG, we go beyond design. By deeply understanding the unique qualities of your company, we create custom solutions that ensure each ring not only symbolizes honor but also tells the company story with unparalleled precision.

Advanced 3D Design and Prototyping:

Leveraging cutting-edge 3D design technology, we provide precise renderings and physical prototypes with remarkable speed. Every detail is refined to ensure that the final product not only meets but exceeds your expectations.

Smart Cost Management:

From small-batch customizations to large-scale wholesale production, we deliver high-quality results with optimized cost solutions. Trust HUNGKUANG to provide seamless transitions from design to production, ensuring your complete confidence at every step.

Dependable Supply Chain and Timely Delivery:

Our robust supply chain ensures consistent quality and punctual delivery, so your products arrive exactly when you need them. With HUNGKUANG, you can trust that no moment will ever be missed.

Uncompromising Quality Assurance:

From premium gold and platinum to exquisite diamonds and gemstones, every product undergoes meticulous inspections at each stage. The result is a timeless masterpiece that embodies both enduring value and exceptional artistry.

HUNGKUANG Can Also Help with Pre-Event Marketing

HUNGKUANG will provide professional 3D rendering videos and high-quality photos after the design is completed, empowering you to showcase and promote your championship ring instantly. Whether for impactful marketing campaigns or brand exposure, these visual tools will help you capture attention and emphasize the exceptional charm of your design.

Reach Out to HUNGKUANG Today to Craft Your Custom Championship Ring!

A symbol of glory and achievement, a championship ring preserves precious moments and turns them into timeless memories. Whether celebrating a team triumph or honoring personal milestones, we provide expert design and production services to create a truly unique masterpiece. Let HUNGKUANG Jewelry transform your success into a treasured work of art. Contact Us Now and Let Your Moment of Glory Shine Brilliantly!

Click the "Product Inquiry Form" or the button below to connect with HUNGKUANG and preserve your milestones for eternity.